The Future of Purging is BritePurge®

BritePurge® are High Performing Purging Compounds designed to reduce the costs associated with purging plastic processing equipment. Created and supported by the experts that developed some of the industries leading products and technologies in purging compounds, Britec Solutions Inc. offers comprehensive solutions to ensure the right product– for the right process– to achieve the best result.

BritePurge® Packs

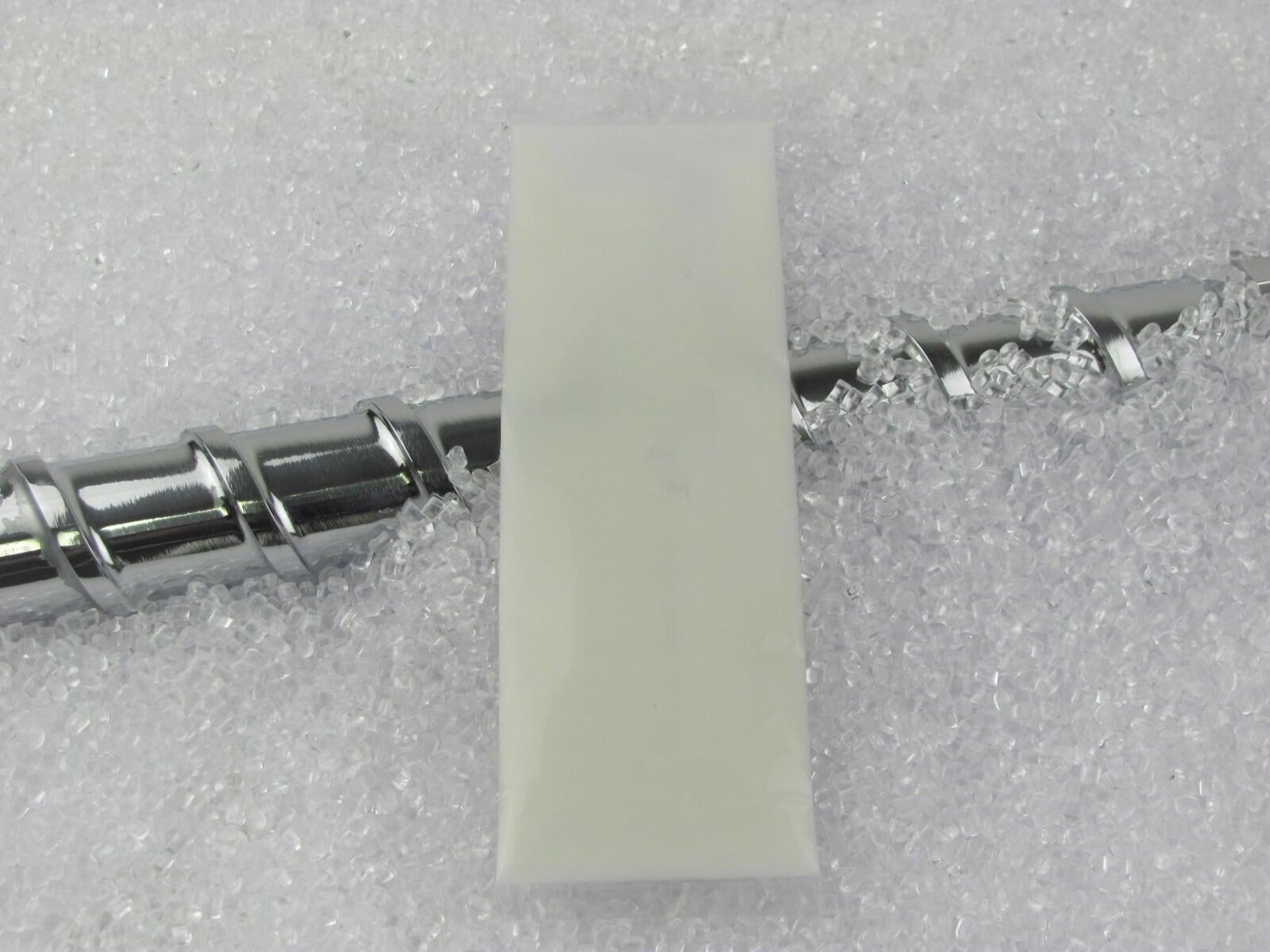

Efficient, Effective and EconomicalSimply Drop the BritePurge® Pack in the Feed Throat and Follow with ResinAvailable in 1 oz. and 3 oz. Single Use Packs

Introduced in 2006 at NPE Chicago and Britec is still introducing the most innovative purging products.We are the Original Designer and Manufacturer of the Single Use Purge Products.

We are the Original Designer and Manufacturer of the Single Use Purge Products.

BritePurge® is the result of a great journey in purging technologies

BritePurge® is the result of a great journey in purging technologies

BritePurge® has the right product– for the right process– to achieve the best result

Looking for a purging compound that works?

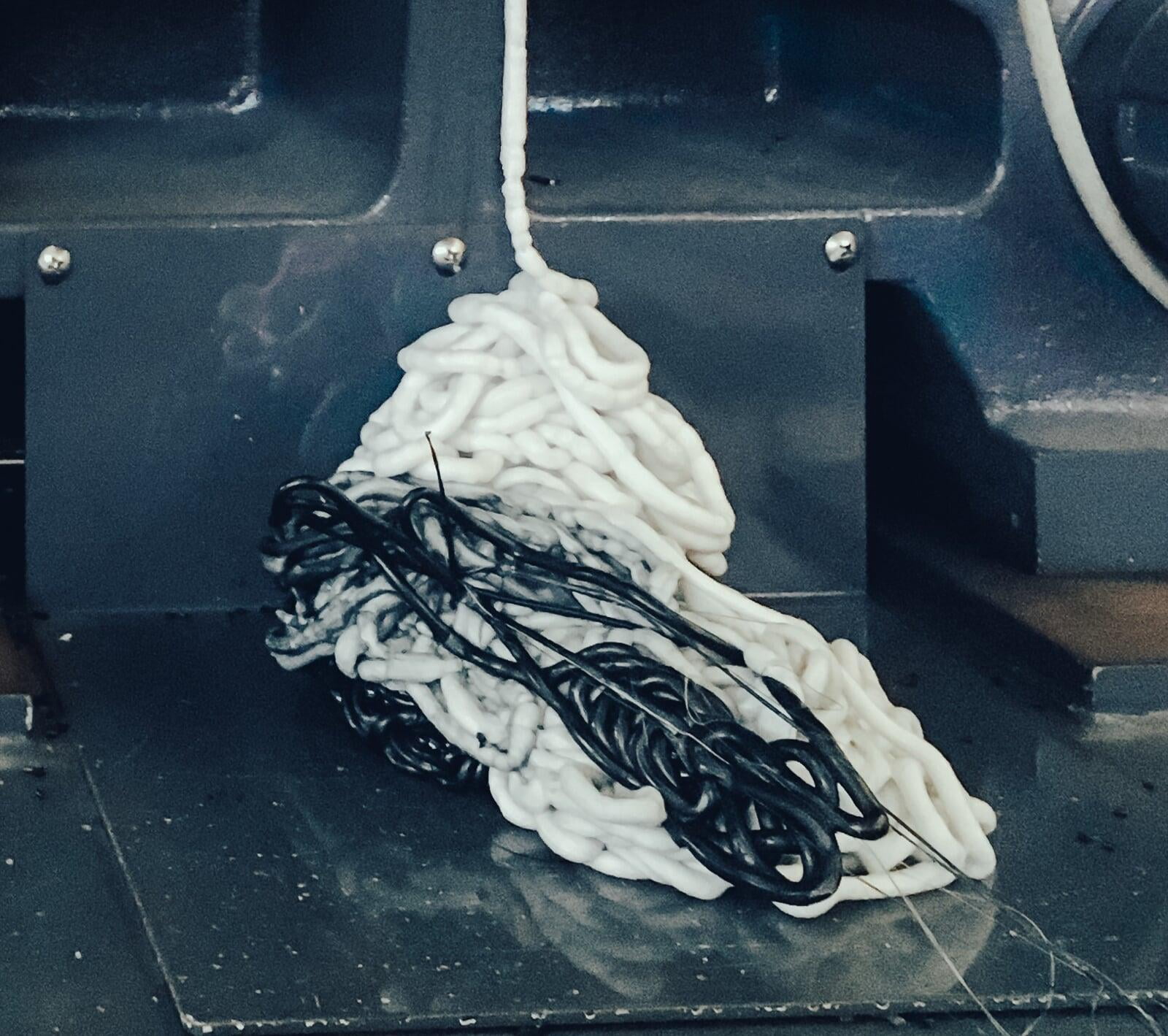

Transitioning from one color to another creating too much downtime?

Trying to eliminate contamination that causes rejects?

BritePurge® has the solution.

BritePurge® Features

- Both Concentrate and Ready-to-Use grades available

- High thermal stability to encourage barrel sealing for shutdowns

- Contains metal deactivators that promote resin release from the screw and barrel

- Formulated for exceptional compatibility with resins

- Products specifically designed for Hot Runner and Manifold Systems

BritePurge® Benefits

- Reduce downtime and screw-pulls

- Produces faster color and resin changeover

- Effectively removes carbon build-up and color contamination

- Decreases rejects and scrap

- Promotes cost savings

Looking for a purging compound that works?

Transitioning from one color to another creating too much downtime?

Trying to eliminate contamination that causes rejects?

BritePurge® has the solution.

BritePurge® Packs consists of a advanced functioning liquid purge compound, pre-measured 1 oz. and 3 oz. and sealed in a poly bag. The highly concentrated purge solution delivers a variety of active ingredients that cause contamination such as carbon build-up, color and degraded resins to release from the metal surfaces of the screw and barrel. Designed to create an effective and efficient purge process that relates to savings.

Benefit and Features:

- Easy to Use;

- Reduces inventory space;

- Considered GRAS (Generally Recognized As Safe) by the FDA and compliant for use in applications that are in direct contact with food;

- The active ingredients are polymer-free and compatible with ANY thermoplastics resin- even the high temperature resins;

- Recommended for purging through hot runners; manifolds; check-rings; mixing nozzles; dies and screen packs;

- Contains no abrasive or corrosive components that can damage mold surfaces;

- Parts can be molded during purge cycle and scrap can be reused into a utility application like black;

- Reduces costs associated with purging

Easy dosing for the BritePurge® Packs are typically One (1)- 1 oz. Packet for every One Inch (1”) of screw diameter. Place the entire packet into the feed throat and follow-up with the purge resin. For tough purging applications, allow 5-10 minutes of soak time, modification to the process profiles are not typically necessary.

Example of Dosage:

1” Screw diameter would require 1oz. or One- 1 oz. BritePurge® Pack

2” Screw diameter would require 2 oz. or Two- 1 oz. BritePurge® Pack

3” Screw diameter would require 3 oz. or Three- 1 oz. or 1- 3 oz. BritePurge® Pack

For applications that require multiple doses- BritePurge® Packs should be spaced evenly and follow with the desired resin until the entire barrel is charged.

Contact Britec Solutions Inc for Purging Guidelines, Technical Data Sheets or request a sample at: orders@britecsolutions.com

BritePurge® is a registered Trademark of Britec Solutions Inc. 2021. All Rights Reserved

BritePurge® is a registered Trademark of Britec Solutions Inc. 2021. All Rights Reserved

BritePurge® is a registered Trademark of Britec Solutions Inc. 2021. All Rights Reserved

BritePurge® is a registered Trademark of Britec Solutions Inc. 2021. All Rights Reserved

BritePurge® is a registered Trademark of Britec Solutions Inc. 2021. All Rights Reserved

BritePurge® Loader is an air-operated feeding system specifically designed to convey your pellet purge product into the feed throat of the process equipment. No motors or electrical components, required 70-80 psi compressed air. Portable and indutrial light-weight design can be moved arounf the production floor easily. Dosing adjustment is simple and responsive- allowing the user to modify the volume of feed without climbing on the equipment. Simply place the pick-up wand into the purge compound container (box/barrel/gaylord), attach to supply hose to the hopper feeder, adjust dosing controller, and begin purging. Simple,easy to us and eliminates over usage of purge compounds.

Technical Data Sheet (TDS)

Drawings (DRW)

Accessories List

C ontact Britec Solutions Inc for Purging Guidelines, Technical Data Sheet; Drawings; and Accessories List at: orders@britecsolutions.com

BritePurge® is a registered Trademark of Britec Solutions Inc. 2021. All Rights Reserved

.png)